ProTek® Lifecycle cost

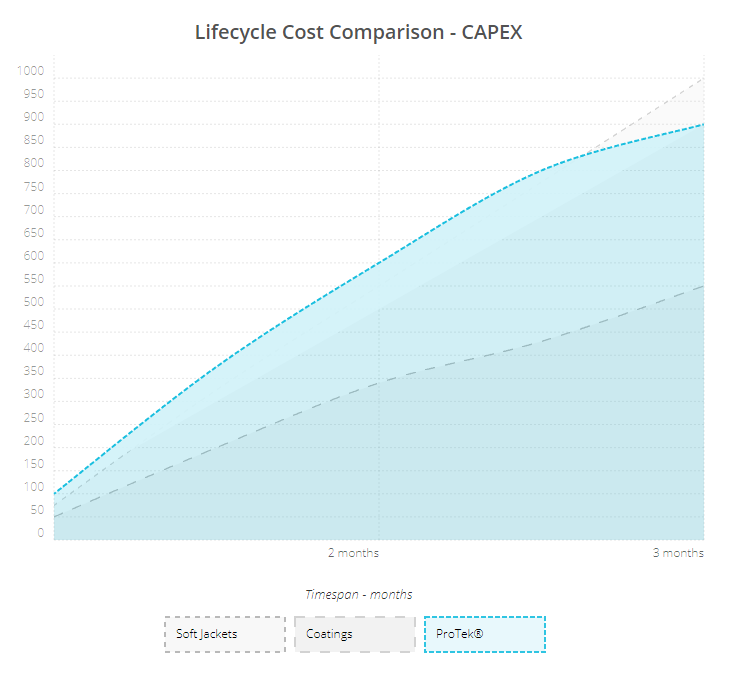

The above graph shows the CAPEX cost comparison between intumescent coatings, soft jackets and ProTek®.

There is zero additional operating costs for ProTek® PFP systems, whereas the need for inspection, maintenance and repair results in additional costs for conventional soft jackets or PFP coating materials. In severe conditions soft jackets and PFP coatings may need replacement during the life of the platform.

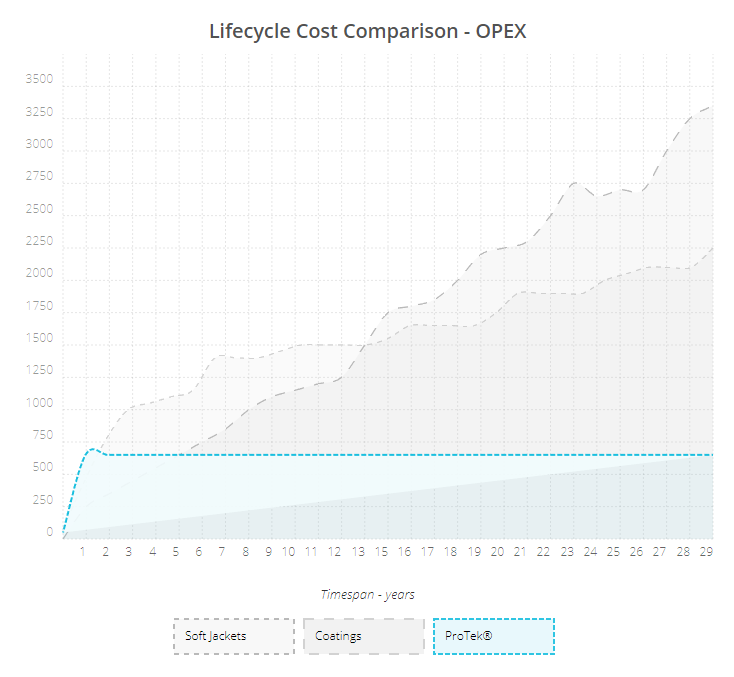

The graph below shows total cost of ownership over a 30 year period. This clearly shows the effect of the inspection, maintenance, repair and replacement cycle required of coatings and soft jackets. There are no such requirements for ProTek® system so the operating costs are zero yielding a much lower lifecycle cost over the platform life.